... and was able to have many interesting conversations about the latest trends and the requirements of your new projects. We were happy to take the opportunity to share our many years of expertise in the field of Film Insert Molding (FIM).

Most of the discussions centred on the integration of functions and the design of future-oriented surfaces using two different decors - one by day and another, that only becomes visible when backlit (ShyTech). Our radar- and lidar-permeable Transparent Printed Heater (TPH) and our previously announced joint project FIM-SlimLight, with very thin surface lighting from edge to edge, also met with great interest.

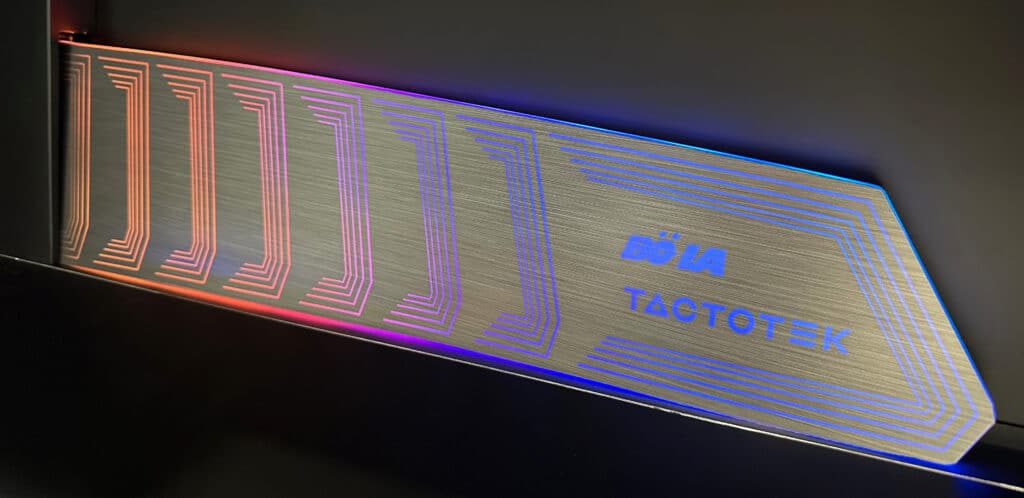

As a TactoTek® licence holder, we were delighted to be able to demonstrate TactoTek's new IMSE® SurfaceLight with dynamic lighting from edge-to-edge, using the example of various decors created by BÖ-LA.

With a positive conclusion, we would like to thank all visitors and business partners that we were able to welcome to our stand and are already looking forward to the next event.

Oulu, Finland/Radevormwald, Germany (17 December, 2021) - TactoTek® (www.tactotek.com), the Finland-based company that develops and licenses Injection Molded Structural Electronics (IMSE®) technology, and BÖ-LA Siebdrucktechnik GmbH (www.boela.de), one of the world's leading specialists for industrial screen-printing applications, today announced that BÖ-LA signed TactoTek's IMSE Builder® frame license agreement. With IMSE Builder®, BÖ-LA will mass-produce IMSE electronically functional films at BÖ-LA's factories in Germany.

BÖ-LA is one of the world's leading specialists for industrial screen-printing applications and, as a pioneer of the Film-Insert-Molding process (FIM), one of the most recognized and competent technology partners in the field of FIM. It offers all FIM manufacturing processes and tooling know-how from a single source. BÖ-LA has been a well-known partner in TactoTek's supply chain for several years, providing decorative films for TactoTek and its customers. With the new agreement, the cooperation will extend to the mass production printing of more complex functional films used in IMSE solutions. "With our core competencies in decoration processes, 3D-forming and Film-Insert-Molding, BÖ-LA manufactures and supplies decorative assembly groups from a single source. If desired, we can integrate touch-sensitive surfaces and even incorporate illumination," says Mike Böing-Messing, CEO of BÖ-LA. "By licensing IMSE technology, we will extend our competencies to mass producing more complex functional films for a wider range of industry segments, such as automotive, industrial, aviation, consumer, smart home, and medical industries."

TactoTek's IMSE technology combines structure, electronics functions, and aesthetics in light, thin, and rugged smart surfaces. Popular uses for IMSE parts include control panels, functional and styling illumination in automotive, home appliance, and smart home markets. The IMSE training program that BÖ-LA has already started transfers TactoTek's know-how and enables BÖ-LA to mass produce IMSE functional films. The cooperation between TactoTek and BÖ-LA also provides the option for TactoTek`s Licensees to outsource their IMSE functional film printing and forming to BÖ-LA.

Marko Suo-Anttila, SVP Professional Services TactoTek, comments: "Our cooperation with BÖ-LA has been successful for several years, with both TactoTek and our customers being delighted with BÖ-LA's professionalism and high-quality deliverables. Expanding our cooperation is the next logical step in the buildup of an IMSE ecosystem. It proves that mass production supply chains are already available, paving the way to broader adoption of IMSE technology."

About TactoTek

TactoTek is the leading provider of Injection Molded Structural Electronics (IMSE) solutions that integrate printed circuitry and electronic components into 3D injection molded plastics. Leading IMSE use cases include human-machine interfaces (HMI), connectivity and electronic styling features for automotive, smart home, appliances and other markets. TactoTek develops and industrializes IMSE technology, creates mass production ready IMSE prototypes, and licenses IMSE technology for 3rd party IMSE part design and global mass production.

TactoTek is funded by international leaders in finance and industry committed to advancing technology solutions that benefit consumers and the environment. TactoTek investors include 3M Ventures, Repsol Energy Ventures, Faurecia Ventures, Conor Venture Partners, Voima Ventures, Nordic Option Oy, Nidoco AB and Cornes Technologies Limited. For more information, please visit www.tactotek.com.

About BÖ-LA

From its beginnings in 1975 as a small business for promotional items, BÖ-LA Siebdrucktechnik GmbH subsequently developed into one of the leading manufacturers of technical screen-printing films. Today, BÖ-LA is a recognized and competent development partner and supplier to large-scale industries, especially in the business fields of automotive and household appliance industries as well as in the medical and electronics sectors. The company has around 250 employees at three locations in Radevormwald, Germany.

Film-Insert-Molding and innovative backlighting are BÖ-LA's core technologies. However today, BÖ-LA has a wide range of decoration processes as well as a large scope of foil processing and 3D-forming methods. In the field of injection molding, BÖ-LA is just as broadly positioned and offers nearly the full range of insert-molding processes. On top of that, as a specialist in automation and assembly technology, BÖ-LA offers the ready-assembled decorative assembly from a single source - naturally also with function integration.

The automotive industry is in a state of change. E-mobility and autonomous driving bring new challenges and design possibilities for the automobile exterior. Above all for the radiator grille, as a defining design feature.

The BÖ-LA SMART DESIGN team has taken up this trend and, together with a partner, has developed a demonstrator that will be presented for the first time at this year's Fakuma.

The innovative structure and futuristic backlighting enable novel design elements and open up a completely new form of communication with road users.

The screen-printed structures that a customer wanted to have implemented for a new decorative component should be smaller than technically possible. Line thicknesses of less than 0.1 mm are consistently rejected in feasibility assessments for screen printing series production. This is not the case with the BÖ-LA SMART DESIGN team, which has tackled the issue. A solution for the realisation of line widths with only a few hundredths of a line was not in the drawer - precisely because this was previously not possible in series production and could only be realised by means of other printing technologies, such as gravure printing. It was only in cooperation between BÖ-LA SMART DESIGN and external partners that a way could be found to enable such fine structuring in screen printing.

The new technology is particularly suitable for high-quality FIM trim parts with sophisticated decors such as metal structures, metal meshes or brushed structures - of course much more cost-effective than real metal materials and, above all, backlit.

The team from BÖ-LA SMART DESIGN is happy to provide interested customers with our Micropattern sample fan with a wide selection of decors.

As part of a joint project between BÖ-LA and a Tier 1 customer, this impressive demonstrator in the form of a completely redesigned mini centre console was presented for the first time at Fakuma 2018. The entire unit features a black panel design and is equipped with proximity sensors. Under the completely piano-black surface, the entire control elements only become visible when the hand approaches and are operated via BÖ-LA's 3D-Sensitive-Touch,

You won't find a gear selector lever or buttons for the seat heating - both are integrated into the smart piano lacquer surface via touch functions. Just like two innovative new features such as a cupholder with stepless temperature regulation and optical temperature or a docking station for inductive charging of your mobile phone.

The black panel effect, i.e. the disappearance of a graphic or decor that only becomes visible when backlit, is widely known. Less well known, however, is that the same disappearing effect is also possible for chrome surfaces. For this purpose, BÖ-LA uses backlit films with high-quality chrome surfaces that can be printed on both sides, are moldable and can be injection-molded using the FIM process. These foils are available in a wide range of chrome tones. In addition to high-gloss chrome, a wide variety of dark chrome, matt chrome and brushed chrome surfaces are also possible.

At BÖ-LA you can take this literally - because we have already received several awards for excellence in training indeed. In 2019, BÖ-LA's trainee was honored as the best media technologist in North-Rhine-Westphalia in the field of screen printing.

You can find more information about our training at Jobs and career

XMAPP certification is designed to address supply chain challenges by improving collaboration between MacDermid Enthone Industrial Solutions (MEIS), processor, system supplier and OEM. The certification process identifies issues and assesses the risk of potential new projects for processors and system suppliers. XMAPP gives OEMs the confidence to receive high product quality and consistent processes from experienced and audited processors working to the same standard worldwide.

BÖ-LA is proud to be one of the first processors worldwide with XMAPP certification from MacDermid Enthone Industrial Solutions (MEIS).

BÖ-LA achieves the highest level of this certification with XMAPP Level 4 and is thus able to handle even the most demanding projects.

Film-insert-molding (FIM) pioneer BÖ-LA to add IMSE solutions to product mix

OULU, FINLAND/RADEVORMWALD, GERMANY (10 April 2019) - Today, BÖ-LA and TactoTek® jointly announced that they have signed an agreement for BÖ-LA to market and sell injection moulded structural electronics (IMSE™) solutions. This partnership brings together leaders in their respective technology domains to advance the market for integrating electronic functionality within molded plastics.

"The vast majority of our IMSE customer cases are for user interfaces that require flawless cosmetics. BÖ-LA's film-insert molding skill is recognized by leaders in automotive, appliance and electronics markets as consistently meeting the highest standards," said Sini RytkyTactoTek VP, Product Management. "With their close customer relationships and deep technical knowledge that includes printed electronics, BÖ-LA is in an ideal position to determine the best fit of technologies for each customer project."

BÖ-LA has a distinguished reputation for technology innovation and has specific expertise in delivering high quality cosmetic surfaces, technical screen printing, illumination and film-insert-molding (FIM) which is also known as in-mold labelling (IML).

According to Dirk Lange, Head of Sales, at BÖ-LA, "We have been actively involved in developing and commercializing techniques for adding electronic functions to cosmetic surfaces, including integrating printed electronics in 3D-formed FIM parts. With TactoTek's IMSE technology, we can also integrate electronic components within these moulded structures which increases integrated functionality and streamlines production for the right designs."

On 1400 sqm, the modern hall still offers plenty of space for the growing injection molding production, a new mold storage in a separate fire protection area as well as best production conditions for Film-Insert-Molding XXL.

We are already looking at the automotive interior of tomorrow. In the cockpit design of the future, control elements merge with decorative components. A new generation of decorative-functional FIM components is emerging that will be one thing above all - large. The new hall sets the course for the series production of large-format, three-dimensionally shaped FIM components. The crane runways are designed for large tools weighing up to 8 tonnes.